High-Speed Infrared Drying Tunnel Kiln for Pulp Molding | Multi-Layer Continuous Drying Production Line

Product Details:

| Place of Origin: | China |

| Brand Name: | OSMANUV |

| Certification: | ISO9001 |

| Model Number: | OSM-IR-1320 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Wooden Box |

| Delivery Time: | 30~45 Days |

| Payment Terms: | T/T |

| Supply Ability: | Negotiation |

|

Detail Information |

|||

| Type: | Drying Machine | Powersource: | Electricity |

|---|---|---|---|

| Heating Element: | Infrared Quartz Tube | Coolingsystem: | Forced Air Cooling |

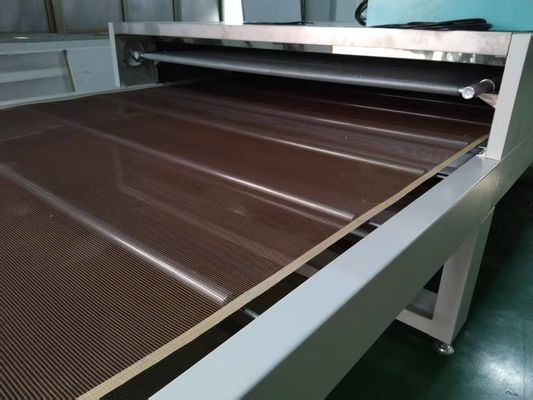

| Condition: | New | Colorconveyor: | Teflon Conveyor Belt |

| Effective Dry Width: | 1320mm | Feature: | Energy Saving |

| Band Name: | OSMANUV | ||

| Highlight: | high-speed infrared drying kiln,pulp molding drying tunnel,multi-layer continuous drying line |

||

Product Description

High-Speed Infrared Drying Tunnel Kiln for Pulp Molding | Multi-Layer Continuous Drying Production Line

1. Composition of Production Line

This system is an integrated drying solution comprising: an infrared heating tunnel section, a multi-layer conveyor system with customizable mesh belts, a hot air circulation and ventilation unit, a cooling zone, a centralized electrical control cabinet, and a temperature monitoring system. It is designed for seamless connection with upstream molding and downstream packaging stations.

2. Product Description

This industrial-grade infrared drying tunnel is engineered specifically for efficiently drying molded pulp products, such as food trays, plates, industrial packaging, and paper pulp tableware. Utilizing efficient infrared radiation and forced hot air convection, it ensures rapid and uniform moisture removal, significantly reducing drying time, improving product dimensional stability, and increasing overall production line throughput.

3. Technical Parameters

| Parameter Category | Specification |

|---|---|

| Model | IRD-PM-1500 (Example, customizable) |

| Heating Method | Medium-wave / Far-infrared ceramic heaters (selectable) |

| Max. Operating Temperature | 150°C |

| Conveyor Belt | Multi-layer mesh belt, customizable width (e.g., 1200mm, 1500mm) |

| Drying Tunnel Length | Standard 10 meters (customizable from 5m to 20m) |

| Number of Drying Tiers | 3-6 tiers (configurable) |

| Conveyor Speed | 0.5 - 5 m/min (variable frequency control) |

| Total Installed Power | Approx. 120 kW (customizable based on length and configuration) |

| Control System | PLC + Touchscreen HMI, with independent temperature control for each zone |

| Power Supply | 380V / 50Hz / 3Phase (or as per local standard) |

4. Application

Ideal for drying various molded pulp products, including but not limited to: Pulp tableware (plates, bowls, cutlery), Egg trays and cartons, Fruit and product packaging trays, Industrial protective packaging.

5. Customization

We offer extensive customization options to meet specific production needs. Key customizable elements include: the length, width, and number of tiers of the drying tunnel; infrared heater type and layout; conveyor belt material (e.g., coated wire mesh); and integration with specific ventilation or heat recovery systems.

6. Features & Advantages

-

Rapid & Uniform Drying: Infrared penetrates to dry from the inside out, reducing time and preventing surface crusting.

-

High Energy Efficiency: Direct radiation transfer minimizes heat loss compared to conventional convection ovens.

-

Space-Saving Design: Vertical multi-layer structure maximizes drying area within a small footprint.

-

Precise Control: Zoned temperature and speed control allows optimization for different products and moisture levels.

-

Reduced Warping: Even heating promotes uniform shrinkage, improving product flatness and quality.

7. Support and Services

-

On-site or remote installation guidance.

-

Comprehensive operator training.

-

One-year warranty on all components.

-

Lifetime technical consultation and spare parts support.

8. Packing and Shipping

The equipment is disassembled into major modules for shipping. All parts are securely packed in wooden crates with waterproof and shock-absorbing materials. Shipping terms (FOB, CIF, etc.) are negotiable. Lead time is typically 8-10 weeks after final design confirmation.

9. FAQ

-

Q: Can this dryer handle different shapes and weights of pulp products?

-

A: Yes. The customizable mesh belt and adjustable airflow system can be tailored to accommodate products from lightweight egg trays to heavier packaging.

-

-

Q: How does it compare to traditional hot air ovens in energy consumption?

-

A: Infrared drying is typically 20-30% more energy-efficient as it directly heats the product, not the surrounding air, leading to faster cycle times and lower operating costs.

-

-

Q: Are your machines compliant with international safety standards?

-

A: Yes. Our electrical systems are designed to meet CE (or relevant local) standards. Specific certifications can be discussed as a customization option.

-