Natural Gas-Fired Drying & Spin Coating Line for Cement Fiber Board and Calcium Carbonate Board

Product Details:

| Place of Origin: | China |

| Brand Name: | OSMANUV |

| Certification: | ISO9001 |

| Model Number: | OSM-TRQ-1320 |

| Document: | Natural Gas Drying Machine.pdf |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Wooden Box |

| Delivery Time: | 30~45 Days |

| Payment Terms: | T/T |

| Supply Ability: | Negotiation |

|

Detail Information |

|||

| Warranty: | 1 Year | Conveying Speed: | 0.3-2 M/min |

|---|---|---|---|

| Coating Width: | 1320mm | Volume: | 420L |

| Cooling: | Water Cooling | Machine Type: | Seasoning Grinder |

| Dry Automation: | High Automation | Dimensions: | Customizable Based On Capacity And Installation Requirements |

| Automatic Grade: | Automatic | ||

Product Description

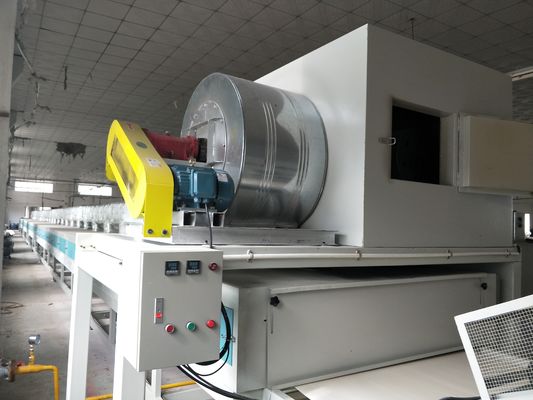

Natural Gas-Fired Drying & Spin Coating Line for Cement Fiber Board and Calcium Carbonate Board

1. Composition of Production Line

This fully automated, inline system integrates coating and drying into one seamless process:

-

Panel Loading & Alignment Conveyor: Automatic feeding with edge alignment.

-

Surface Pre-Treatment Zone (Optional): Plasma or flame treater for enhanced coating adhesion.

-

Precision Spin Coating Station: Single or multi-station rotary table with programmable dispensing and high-speed spinning for uniform internal coating.

-

Natural Gas-Fired Conveyorized Drying Tunnel: Multi-zone, temperature-controlled tunnel using clean natural gas combustion for efficient and uniform heating.

-

Cooling Zone: Forced air cooling section to stabilize panels before handling.

-

Unloading & Stacking Conveyor.

-

Central Control Cabinet & HMI: Integrated PLC system for full parameter control and monitoring.

2. Product Description

This specialized production line is engineered for applying and curing uniform, high-performance internal coatings on cement fiber boards and calcium carbonate boards. It combines precision spin coating technology with an energy-efficient natural gas drying system. The spin coater ensures a pinhole-free, consistent film thickness, while the gas-fired tunnel provides deep, controllable, and cost-effective drying essential for the porous structure of construction panels, resulting in superior waterproofing, weather resistance, and surface quality.

3. Technical Parameters

| Category | Parameter | Specification / Description |

|---|---|---|

| Core Capacity | Suitable Panel Size (Max) | Customizable (Standard: 1300mm x 2500mm) |

| Production Cycle (Dependent on dry time) | Customizable, typically 1-3 panels/minute | |

| Coating Application Method | Precision Programmable Spin Coating | |

| Drying System | Heating Method | Natural Gas Direct/Indirect Fired Burners |

| Drying Tunnel Temperature Range | Ambient ~ 250°C (adjustable in zones) | |

| Heat Circulation | Forced convection with high-efficiency fans | |

| Energy Efficiency Class | High (Compared to traditional electric heating) | |

| Coating Specifications | Coating Type | Compatible with water-based acrylics, epoxy, specialized barrier coatings. |

| Coating Thickness (Dry) | 10 - 50 µm (adjustable, uniformity >95%) | |

| Line Specifications | Line Footprint (LWH) | Customizable (Approx. 25m x 4m x 3m for a standard configuration) |

| Conveyor Type | Chain drive with friction rollers or mesh belt. | |

| Control System | Siemens/Mitsubishi PLC with 10-inch Touchscreen HMI. | |

| Utility Requirements | Natural Gas Pressure & Consumption | Customizable based on thermal load; Standard requirement: 0.05-0.1 MPa. |

| Power Supply | 380V, 3-Phase, 50Hz (Customizable) | |

| Compressed Air | 0.6-0.8 MPa, Clean & Dry. |

4. Application

-

Internal Waterproof/Weatherproof Coating: For cement fiber boards used in exterior siding, roofing, and facades.

-

Primer or Sealer Coating: For calcium carbonate boards before further finishing.

-

Functional Coating Application: Fire-retardant or moisture-barrier coatings on construction panels.

5. Customization

This line is highly customizable to fit your exact factory layout and product specifications:

-

Panel Size & Throughput: Maximum panel dimensions and line speed are customizable.

-

Drying Tunnel Length & Zoning: The number and length of heating/cooling zones can be customized based on your required drying curve and output.

-

Spin Coater Configuration: Number of spin stations, rotation speed profiles, and dispensing systems are customizable.

-

Fuel & Control Integration: Can be customized for dual-fuel (gas/oil) capability or for specific factory automation protocols.

6. Key Features

-

Deep & Uniform Drying: Natural gas heating is ideal for thorough drying of dense, porous construction boards without surface crusting.

-

Precision Coating: Spin coating technology guarantees unmatched film uniformity and material efficiency on flat panels.

-

Lower Operating Cost: Natural gas as a fuel source typically offers significant cost savings compared to pure electric drying systems.

-

Robust Construction: Designed for continuous, heavy-duty industrial operation with low maintenance requirements.

-

Intelligent Control: Precise temperature profiling and recipe management for different products via the HMI.

7. Support and Services

-

Feasibility & Layout Planning: Free initial consultation and production line layout design.

-

Installation & Commissioning: Supervised on-site installation, mechanical and electrical setup, and process fine-tuning.

-

Training: Comprehensive operational and maintenance training for your engineers and operators.

-

After-Sales: 18-month core machinery warranty. 24/7 remote technical support and readily available spare parts.

8. Packing and Shipping

-

Packing: Major modules (drying tunnel, coating station, control cabinet) are disassembled and securely packed in heavy-duty, weatherproof wooden crates suitable for ocean freight.

-

Shipping: We handle all export procedures and ship worldwide via sea freight (FOB/CIF terms). Detailed installation manuals and electrical diagrams are included.

9. FAQ

Q1: Why choose natural gas drying over electric infrared for these boards?

A: Natural gas provides convective heat, which penetrates deeply into the porous structure of cement fiber boards, ensuring moisture is removed from the core. Electric IR often only heats the surface, risking blistering or incomplete curing.

Q2: Can this line handle both very small and large panel sizes?

A: Yes, through customization. The conveyor width, fixture design, and spin coater chuck size can be customized to accommodate a wide range of panel sizes, ensuring flexibility for your production.

Q3: How is temperature uniformity ensured across the wide panel in the drying tunnel?

A: Our tunnel features multiple independently controlled temperature zones and optimally positioned high-velocity air nozzles, ensuring a temperature variation of less than ±5°C across the panel width. The design is further customizable for extra-wide panels.

Q4: What is the typical lead time for such a customized line?

A: The lead time is typically 16-20 weeks from order confirmation, which includes detailed engineering, manufacturing, factory testing, and packing.

Q5: Do you offer a coating trial service with our own panels?

A: Yes. We strongly recommend a coating and drying trial at our facility using your specific panels and coating materials. This allows us to finalize the optimal process parameters and customize the line accordingly before manufacturing.