Cost-Effective Natural Gas Drying for Enhanced Calcium Silicate Board Production

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | OSMANUV |

| Certification: | ISO9001 |

| Model Number: | OSM-LRHG-1320T |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiation |

| Packaging Details: | WOOD PACKAGING |

| Delivery Time: | 35 days |

| Payment Terms: | T/T |

| Supply Ability: | Negotiation |

|

Detail Information |

|||

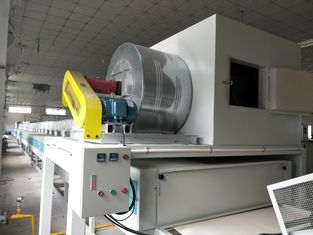

| Product Name: | 28 Meters Natural Gas Drying Machine | Dimension(l*w*h): | Customized Size,28000mm *2400mm *3140mm |

|---|---|---|---|

| Power: | 24kw | Voltage: | 380V/50HZ |

| Coating Width: | 1320mm | Coating Speed: | Adjustable,0.5-8m/min |

| Warranty: | 1 Year | Condition: | New |

| Highlight: | natural gas drying machine,industrial calcium silicate board dryer,cost-effective gas drying equipment |

||

Product Description

Cost-Effective Natural Gas Drying for Enhanced Calcium Silicate Board Production

Product Description

This natural gas drying line is specifically engineered for calcium silicate boards, providing uniform heat distribution and precise temperature control throughout the drying process. The system ensures optimal moisture removal while maintaining board integrity and dimensional stability.

Technical Parameters

| Parameter | Specification |

|---|---|

| Model |

OSM-LRHG-1320T |

| Heating Source | Natural Gas Burner System |

| Maximum Temperature | 300°C |

| Conveyor Width | 1320 mm (Customizable) |

| Drying Zones | 6 zones (Customizable) |

| Fuel Consumption | 15-25 m³/h |

| Control System | PLC + HMI Touch Screen |

Application

Drying and curing of calcium silicate boards, fireproof panels, and architectural ceiling materials.

Customization

-

Customizable drying zone configuration

-

Customizable conveyor speed and width

-

Customizable temperature profiling

Feature

-

Uniform heat distribution

-

Precise temperature control

-

Energy efficient operation

-

Robust construction

Support and Services

-

Installation supervision

-

Operator training program

-

12-month warranty

-

Technical support

Packing and Shipping

-

Heavy-duty wooden crate

-

Weatherproof packaging

-

Professional export standards

FAQ

Q: What is the energy consumption rate?

A: Average consumption is 18-22 m³/h depending on production requirements.