High-Efficiency Z-Fold Drying Line for Composite Panels & Furniture Boards - Maximized Throughput & Energy Savings

Product Details:

| Place of Origin: | China |

| Brand Name: | OSMANUV |

| Certification: | ISO9001 |

| Model Number: | OSM-ZY-1320 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Wooden Box |

| Delivery Time: | 30~45 Days |

| Payment Terms: | T/T |

| Supply Ability: | Negotiation |

|

Detail Information |

|||

| Material: | Carbon Steel, Stainless Steel, Etc. | Type: | Industrial Machine |

|---|---|---|---|

| Heat Source: | Gas Or Electric Or Steam Heating | Application: | Drying Of Various Materials In Industries Such As Food, Chemical, Pharmaceutical, And Textile |

| Layer: | Two Layers | Condition: | New |

| Payment: | T/T | Heating Area: | 9 Square Meters |

| Highlight: | Z-fold drying line for composite panels,Industrial drying machine with energy savings,High-efficiency furniture board drying line |

||

Product Description

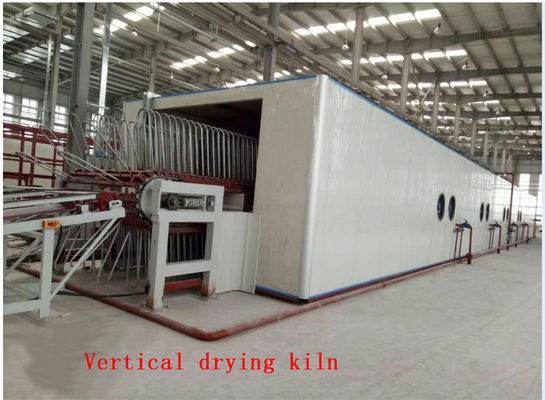

High-Efficiency Z-Fold Drying Line for Composite Panels & Furniture Boards - Maximized Throughput & Energy Savings

Product Description:

Our High-Efficiency Z-Fold Drying Line is engineered for continuous, high-volume drying of coated and laminated panels. Utilizing a patented z-fold (accordion-style) conveyor system, it dramatically increases the residence time of panels within a compact footprint, ensuring complete and uniform curing of water-based or solvent-based coatings, paints, and adhesives. This design optimizes heat transfer and incorporates advanced heat recovery, leading to superior energy efficiency and a significant reduction in operating costs compared to traditional straight-line dryers.

Technical Parameters:

| Parameter | Details/Range |

|---|---|

| Model Series | ZF-DL-HP Series (Customizable) |

| Max. Panel Size (WxL) | 1300mm x 2800mm (Customizable) |

| Conveyor System | Z-Fold (Multi-Tier) Chain Conveyor |

| Heating Method | Indirect Gas/Diesel, Electric, or Steam (Customizable) |

| Drying Temperature Range | Ambient - 120°C (Adjustable in zones) |

| Heat Source Power | 600,000 - 1,200,000 kcal/h (Customizable) |

| Control System | Centralized PLC with Touchscreen HMI |

| Line Speed | 0.5 - 5.0 m/min (Variable) |

| Insulation | High-density mineral wool for optimal thermal efficiency |

Composition of Production Line:

Panel Loading/Auto Feed -> Pre-Drying Section (Air Knife/IR) -> Main Z-Fold Drying Tunnel -> Cooling Section -> Unloading/Stacking Station.

Application:

Ideal for drying painted furniture boards (MDF, particleboard), laminated composite panels, coated decorative wall panels, and door skins after finishing processes.

Customization:

This line is highly customizable. Key options include the number of drying tiers (to adjust total dwell time), specific heating sources to match your facility's utilities, customized internal airflow designs for specific coatings, and integration with upstream coating machines.

Feature:

-

Space-Saving Design: Z-fold conveyor maximizes drying length within a minimal floor area.

-

Uniform & Consistent Drying: Multi-zone temperature control ensures even heat distribution across all panels.

-

High Energy Efficiency: Recirculated hot air and excellent insulation reduce energy consumption by up to 35%.

-

Robust Construction: Heavy-duty chain conveyor handles heavy panels with stability.

-

Easy Maintenance: Ample access doors and a modular chamber design simplify cleaning and service.

Support and Services:

-

Turnkey project management from layout design to commissioning.

-

On-site installation supervision and comprehensive operator training.

-

Annual preventive maintenance contracts and 24/7 remote technical support.

-

Guaranteed supply of original spare parts.

Packing and Shipping:

-

Major sections (chambers, conveyors) are pre-assembled and shipped in robust, seaworthy crates.

-

Electrical panels and sensitive instruments are packed separately in waterproof boxes.

-

All shipments include detailed packing lists, assembly drawings, and installation manuals.

FAQ:

-

Q: How does the Z-Fold design save energy compared to a straight tunnel dryer?

-

A: The vertical stacking allows for excellent heat stratification and recirculation within a sealed chamber, minimizing heat loss to the environment. The compact design also reduces the surface area requiring insulation.

-

-

Q: Can this line handle panels with different curing temperature requirements?

-

A: Yes. The independently controlled heating zones allow you to create a customized temperature profile, with higher temperatures at the entrance and lower at the exit, perfectly suited for staged curing.

-

-

Q: What is the typical lead time for a customized line?

-

A: Lead time varies based on the level of customization and specifications. A standard configuration is typically 10-12 weeks from order confirmation to shipment.

-