High-Speed Automatic Rotary Coating Line for Pulp Molded Food Packaging and Industrial Packaging Interior Coatings

Product Details:

| Place of Origin: | China |

| Brand Name: | Osmanuv |

| Certification: | CE |

| Model Number: | OSM-XT-1024T |

| Document: | PULP MOLDING AUTOMATIC SPIN...NE.pdf |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Wooden box |

| Delivery Time: | 45 Days |

| Payment Terms: | T/T |

| Supply Ability: | Negotiation |

|

Detail Information |

|||

| Application: | Food Packaging, Industrial Packaging | Usage: | Pulp Molded Products |

|---|---|---|---|

| Type: | Spray Coat | Screw: | Double-screw |

| Coating Efficiency: | High Efficiency | Drying Method: | Hot Air Drying |

| Coating Durability: | High Durability | Control System: | PLC Control |

| Highlight: | automatic rotary coating line,pulp molded food packaging machine,high-speed pulp molding coater |

||

Product Description

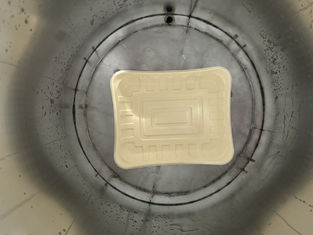

High-Speed Automatic Rotary Coating Line for Pulp Molded Food Packaging and Industrial Packaging Interior Coatings

Composition of Production Line:

This integrated system comprises an automated infeed conveyor, precision rotary coating stations, a multi-stage thermal curing oven, a forced cooling section, quality inspection sensors, and an automated stacking and outfeed system.

Product Description:

Our high-speed rotary coating line is engineered to apply a consistent, ultra-thin internal barrier coating to pulp-molded products like food containers and tableware. It ensures 100% coverage for excellent oil, water, and grease resistance (GRAS/FDA compliant), meeting the highest food safety standards.

Technical Parameters:

| Parameter | Description |

|---|---|

| Line Speed | 10 - 40 cycles/min (customizable) |

| Coating Accuracy | ± 0.005 mm |

| Power Supply | 380V/50Hz/3Phase (Customizable for regional standards) |

| Drying Method | Multi-Zone Hot Air Circulation (Customizable to IR or UV) |

| Control System | Siemens/Allen-Bradley PLC with 15" HMI Touchscreen |

| Coating Material | Water-based, food-grade coatings (customizable for specific formulas) |

| Footprint (LxWxH) | Approximately 20m x 4m x 3m (Customizable based on layout) |

Application:

Internal coating for pulp-molded products such as clamshell containers, plates, bowls, cups, and egg trays requiring FDA-compliant barrier properties.

Customization:

The entire line is highly customizable. We can adjust the number of coating heads, drying length and method, line speed, and control system integration to fit your specific production volume and product specifications.

Feature:

-

Food-Safe Compliance: Designed for use with FDA-approved coatings.

-

Precision & Efficiency: Robotic precision reduces coating material waste by up to 20%.

-

Energy Efficient: Heat recovery systems within the oven reduce energy consumption.

-

Data Tracking: OPC-UA connectivity for data recording and integration with MES systems.

Support and Services:

We provide comprehensive support including installation supervision, operator training, annual maintenance contracts, and 24/7 remote technical assistance. A full set of spare parts is provided initially.

Packing and Shipping:

All equipment is disassembled into modular sections. Components are wrapped in anti-rust film and packed in reinforced wooden crates for secure ocean freight shipping. FOB and CIF terms available.

FAQ:

Q: Can this line handle different product sizes?

A: Yes, the line is highly customizable. Quick-change mandrels and programmable recipes allow for running different product sizes with minimal downtime.