High-Speed Food Safety Tableware Tray Bowl Internal Coating Production Line For Pulp Molding

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | OSMANUV |

| Certification: | CE |

| Model Number: | OSM-XT-2400T |

| Document: | Version 2.0 of 24-station s...on.pdf |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Negotiation |

| Packaging Details: | WOODEN BOX |

| Delivery Time: | 50 DAYS |

| Payment Terms: | T/T |

| Supply Ability: | Negotiation |

|

Detail Information |

|||

| Rotating Height: | Max Is 5300 Mm | Max Product Width: | 500mm |

|---|---|---|---|

| Electric Power: | 380V 50HZ | Total Power: | 160 KW |

| Warranty: | 1 Year | Heating Method: | Electric |

| Heating Source: | Electric IR Heating | Sercive: | Engineer Are Avaliable To Work Overseas |

| Screw: | Double-screw | Type: | Spin Coating Line |

| Drying Length: | 24 M | Productive Capacity: | 4800pcs/8h |

| Highlight: | pulp molding coating machine for tableware,high-speed food safety tray production line,bowl internal coating machine with warranty |

||

Product Description

High Output Food Safety Tableware Tray Bowl Internal Coating Production Line For Pulp Molding

Composition of Production Line:

The High-Speed Internal Coating Production Line for Pulp Molding is engineered for rapid and efficient internal coating processes, incorporating advanced technology to meet the demands of high-volume production.

Product Description:

This specialized production line is optimized for high-speed internal coating applications in pulp molding, ensuring swift and precise coatings on a diverse range of pulp molded products.

Application:

The High-Speed Internal Coating Production Line is ideal for high-volume production environments, catering to industries requiring rapid and precise internal coatings on pulp molded products.

Customization:

This production line offers a range of customization options, including roller speed adjustment, coating thickness control, specialized features integration, and tailored control system configurations to suit specific production requirements.

Technical Parameters:

| Parameter | Description |

|---|---|

| Product Name | Internal Coating Production Line for Pulp Molding |

| Coating Type | Internal Coating |

| Customization Options | Spray Chamber Number, Coating Thickness, Speed Control, Additional Features |

| Material | Stainless Steel |

| Control System | PLC Control System |

| Power Supply | 380V, 50Hz |

| Total Power | 160 kW |

| Coating Speed Range | 40s/group |

| Coating Use Weight | 0.1-5 g |

Features:

- Precision Coating: Ensures uniform and precise internal coatings.

- Customizable Parameters: Tailor settings to match unique product requirements.

- Stainless Steel Construction: Provides durability and corrosion resistance.

- PLC Control System: Offers ease of operation and monitoring.

Support and Services:

Comprehensive support and services include installation assistance, training programs, maintenance support, and responsive technical assistance to optimize production line efficiency.

Packing and Shipping:

The Internal Coating Production Line for Pulp Molding is securely packed for safe transportation. Various shipping options are available to ensure prompt and reliable delivery to the designated location.

FAQ:

Q: Can the coating thickness be customized for specific products?

A: Yes, the coating thickness can be customized to meet the requirements of different pulp molded products.

Q: Are there options for integrating additional features into the production line?

A: Yes, the production line offers customization options to incorporate additional features based on specific production needs.

Q: What industries can benefit from using this production line?

A: Industries focusing on sustainable packaging solutions, such as food packaging, consumer goods, and eco-friendly product manufacturers, can benefit from this specialized production line.

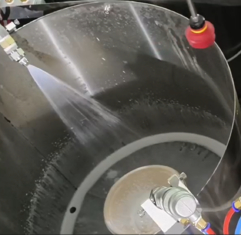

Coating Effect:

![]()

![]()