Double-Station Gantry Robtic Arms for Sheet Metal Maximize Productivity & Flexibility

Product Details:

| Place of Origin: | China |

| Brand Name: | OSMANUV |

| Certification: | ISO9001 |

| Model Number: | OSM-GR-1320T |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Wooden Box |

| Delivery Time: | 30~45 Days |

| Payment Terms: | T/T |

| Supply Ability: | Negotiation |

|

Detail Information |

|||

| Warranty: | 1 Year | Function: | Conveyor Machine |

|---|---|---|---|

| Color: | Customizable | Product Name: | Double-Station Gantry Robtic Arms |

| Machine Type: | Conveyor Machine | Material: | Metal |

| Application: | Automotive Production Line | Type: | Automatic |

Product Description

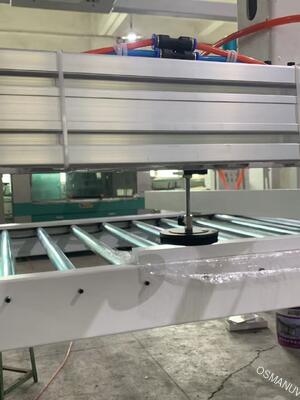

Double-Station Gantry Robtic Arms for Sheet Metal Maximize Productivity & Flexibility

Composition of Production Line

This automated solution integrates a loading table, a dual-station processing zone (compatible with laser cutters, punch presses, etc.), an unloading & sorting area, a customizable material storage system (compact rack or tower warehouse), and a central control unit.

Product Description

Our Double-Station Gantry Loader features a high-rigidity gantry structure with dual, independent loading/unloading heads. It enables simultaneous operation: while one station is processing, the other performs material handling, virtually eliminating machine idle time. The system's modular design allows for customized layout adaptation and can service multiple machine tools (up to 3).

Technical Parameters

Core specifications are indicative and can be customized to your application.

| Category | Parameter | Specification / Description |

|---|---|---|

| Mechanical Structure | Axis Travel (X/Y/Z) | e.g., 6000 mm / 2500 mm / 300 mm [Customizable] |

| Drive System | Precision Servo Motor & Ball Screw / Gear Rack | |

| Positioning Accuracy | ±0.1 mm (Standard), ±0.05 mm (High-Precision Option) | |

| Load & Material | Max. Sheet Size (Loading) | e.g., 6000 mm × 2500 mm [Customizable] |

| Max. Sheet Thickness | 0.5 mm - 25 mm (Standard), up to 50 mm (Heavy-Duty) | |

| Max. Load per Head | 150 kg (Standard), 500 kg+ (Heavy-Duty) | |

| Performance | Max. Speed (X/Y) | e.g., 120 m/min |

| Max. Speed (Z) | e.g., 60 m/min | |

| Control & Power | Control System | Industrial PC + PLC, with customizable HMI |

| Power Supply | 380V / 50Hz / 3-Phase (or customized to local standard) |

Application

Ideal for automating material handling in:

-

Laser Cutting & Punching Lines

-

Flexible Manufacturing Cells (FMC)

-

Stamping & Press Brake Operations

-

Customized integration into existing CNC machining workflows

Customization

We offer extensive customization to ensure perfect fit:

-

Size & Reach: Gantry span, travel length, and Z-stroke.

-

End Effectors: Vacuum, magnetic, or mechanical grippers for specific materials.

-

Control Integration: Tailored software interfaces for seamless communication with your brand of machine tools (e.g., TRUMPF, BYSTRONIC, AMADA).

-

Safety & Options: Integration of light curtains, safety scanners, or vision systems for part recognition.

Feature

-

Dual-Station Design: Drastically reduces cycle time and boosts Overall Equipment Effectiveness (OEE).

-

High Rigidity: Robust welded frame ensures stable, vibration-free operation at high speeds.

-

User-Friendly Programming: Intuitive teach-pendant and graphical interface for easy setup and path planning.

-

Reliable Components: Built with top-tier servo drives, guides, and controllers for long-term durability.

-

Scalable Design: Serves as the foundation for a customizable, fully automated production line with storage and sorting.

Support and Services

-

Professional On-Site Survey & Layout Planning

-

Installation, Commissioning & Operational Training

-

Comprehensive Warranty (typically 12-18 months)

-

Global Spare Parts Support & Remote Diagnostics

-

Lifetime Technical Consultation

Packing and Shipping

-

Machines are custom-crated in heavy-duty, waterproof wooden cases for ocean freight.

-

Critical components are shock-resistant packaged.

-

FOB/CIF terms available. Professional logistics handling ensured.

-

Detailed packing list and installation guide accompany each shipment.

FAQ

-

Q1: What is the lead time for a standard system?

-

A: Approximately 8-10 weeks. Lead time for customized projects depends on scope.

-

-

Q2: Can this system handle different sheet sizes in the same batch?

-

A: Yes, with programmable positioning. For mixed, random-size sheets, a customized vision system is recommended.

-

-

Q3: Do you provide training for operators?

-

A: Yes, comprehensive on-site training for maintenance and programmers is included.

-

-

Q4: Can the loader be integrated with my existing machine?

-

A: Absolutely. Integration feasibility is part of our pre-sales survey. We specialize in customized interfacing.

-