Automated One-Pass Printer for Pulp Molding-Integrated Loading & Printing Solution

Product Details:

| Place of Origin: | China |

| Brand Name: | OSMANUV |

| Certification: | ISO9001 |

| Model Number: | OSM-DP-600 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Wooden Box |

| Delivery Time: | 30~45 Days |

| Payment Terms: | T/T |

| Supply Ability: | Negotiation |

|

Detail Information |

|||

| Driven Type: | Electric | Packaging Type: | Wooder Package |

|---|---|---|---|

| Warranty: | 1 Year | Product Name: | Onepass Printer |

| Color: | You Can Decide | Printing Width: | 600mm |

| Usage: | Digital Prints | Material: | Pulp Molding |

| Highlight: | automated pulp molding printer,one-pass UV coating machine,integrated loading printing solution |

||

Product Description

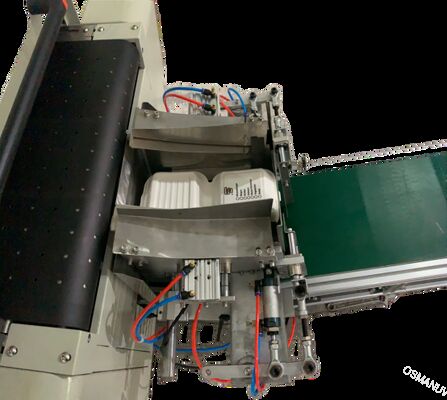

Automated One-Pass Printer for Pulp Molding-Integrated Loading & Printing Solution

Composition of Production Line

This automated printing module seamlessly integrates into your existing pulp molding line. It consists of an Automatic Wet/Dry Blank Feeder (compatible with robotic arm or conveyor input), the Core Onepass Printing Unit, a Dedicated Curing/Drying Tunnel (UV or IR), a Printed Product Unloading & Stacking System, and a Central Control Panel. The system is designed for customized connection points to match your upstream forming and downstream packaging equipment.

Product Description

Our Automated One-Pass Printer revolutionizes post-molding decoration by applying high-quality prints directly onto pulp molded products in a single, continuous operation. Eliminating the need for manual handling or pre-drying, it takes products from the forming press, precisely prints logos, graphics, or information, and delivers them cured and ready for packaging. This integrated solution significantly boosts line efficiency, ensures consistent print registration, and enables cost-effective, short-run customized printing for brands.

Technical Parameters

Standard specifications are listed below, with multiple key aspects available for customization to fit your specific production needs.

| Category | Parameter | Specification / Description |

|---|---|---|

| Printing & Mechanical | Printing Technology | High-resolution Piezo Inkjet Print Heads |

| Max. Printable Area | 400 x 300 mm (Standard), Customizable up to 600 x 500 mm | |

| Print Resolution | Up to 600 x 600 dpi (Software adjustable) | |

| Registration Accuracy | ±0.3 mm (with vision system option for ±0.1 mm) | |

| Handling & Integration | Substrate Compatibility | Wet-pressed (semi-dry) or fully dry pulp products |

| Line Integration Speed | Synchronizable from 10 to 60 cycles per minute (Customizable) | |

| Loading/Unloading Interface | Standard conveyor; Customizable for robot gripper or specific jigs | |

| Ink & Curing | Ink Type | Environmentally Friendly, Water-Based or UV-Curable Pigment Inks |

| Curing System | Instant UV-LED or Efficient IR Drying Tunnel (Selectable) | |

| Control & Power | Control System | Industrial PC with intuitive software, recipe management, and data logging |

| Power Requirements | 220V / 380V, 50/60Hz (Customizable based on plant specification) |

Application

-

Food Service Packaging: Printing logos, certifications, or decorative patterns on plates, bowls, and clamshells.

-

Electronics & Industrial Cushioning: Adding part numbers, brand logos, or handling instructions on protective trays.

-

Custom Branded Packaging: Enabling short runs of customized packaging for events, premium products, or marketing campaigns.

-

Agricultural Seedling Pots: Printing planting instructions or brand identity directly on biodegradable pots.

Customization

We offer flexible customization to ensure perfect integration and performance:

-

Printing Size & Configuration: Tailoring the print width, number of print heads, and color stations (monochrome to full-color).

-

Ink System: Selecting the optimal ink (water-based, UV) for your substrate (wet/dry) and end-use requirements (food safety, abrasion resistance).

-

Material Handling: Customizing the feeder and unloader mechanism to match your product's specific shape, size, and fragility.

-

Software Integration: Developing customized communication protocols to sync with your line's master PLC or MES system.

Feature

-

True In-Line Automation: Eliminates manual transfer, reducing labor costs and handling damage while maximizing throughput.

-

Exceptional Print Quality & Adhesion: Advanced inkjet technology and pretreatment options ensure sharp, durable prints even on porous, textured pulp surfaces.

-

Quick Changeover & Flexibility: Digital design files allow for instant job switching, making short runs and customized batches economically viable.

-

Robust & Reliable Construction: Built for 24/7 industrial environments with easy-access components for maintenance.

-

Sustainable Operation: Utilizes eco-friendly inks and energy-efficient UV-LED curing, aligning with the green ethos of pulp molding.

Support and Services

-

Comprehensive Pre-Installation Site Audit & Integration Planning

-

Professional On-Site Installation, Calibration, and Staff Training

-

12-Month Warranty on the Entire System

-

Dedicated Technical Support Hotline and Remote Diagnostics

-

Preventive Maintenance Plans and Global Spare Parts Network

Packing and Shipping

-

The system is modularized and securely packed in heavy-duty, weatherproof wooden crates.

-

Sensitive components like print heads and electronics are given special anti-static and shock-proof packaging.

-

All shipments include detailed packing lists, assembly drawings, and digital manuals.

-

We manage export documentation and can ship via air or sea based on your requirements.

FAQ

-

Q1: Can this printer handle wet, freshly molded pulp products?

-

A: Yes, it is specifically engineered to print on both semi-dry (wet-pressed) and fully cured substrates. Ink and curing settings are customizable for optimal results on each.

-

-

Q2: How do I change the design being printed?

-

A: Designs are changed digitally in seconds. Simply upload a new graphic file to the printer's computer—no physical plates or screens are needed.

-

-

Q3: What is the operational cost (ink consumption) like?

-

A: Ink consumption is highly efficient due to non-contact, drop-on-demand printing. Exact cost depends on coverage, but the system is designed for economical operation even in customized, short-run jobs.

-

-

Q4: How is color consistency maintained across different batches?

-

A: The system uses closed-loop color calibration and automatic maintenance cycles to ensure consistent, repeatable print quality over time and across production batches.

-