Compact Modular UV Sterilization Unit - Flexible and Space-Saving Solution for Small to Medium-Scale Packaging Lines

Product Details:

| Place of Origin: | China |

| Brand Name: | OSMANUV |

| Certification: | ISO9001 |

| Model Number: | OSM-SJ-1320 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Wooden Box |

| Delivery Time: | 30~45 Days |

| Payment Terms: | T/T |

| Supply Ability: | Negotiation |

|

Detail Information |

|||

| Type: | UV Sterilization Machine | Coating Safety: | High Safety |

|---|---|---|---|

| Rubber Diameter: | 200mm | Application: | Sterilization, Disinfection |

| Powersupply: | 220V/50Hz | Automatic Grade: | Automatic |

| Material: | Stainless Steel | Speed: | 1-10m/min,adjustable |

| Highlight: | compact UV sterilization unit,modular UV irradiation machine,space-saving UV packaging line sterilizer |

||

Product Description

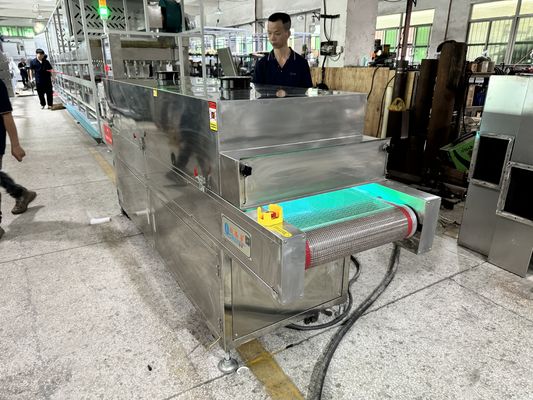

Compact Modular UV Sterilization Unit - Flexible and Space-Saving Solution for Small to Medium-Scale Packaging Lines

Composition of Production Line

Designed for flexibility and minimal footprint, perfect for limited spaces or targeted sterilization points:

-

Unified Stainless Steel Housing: Integrates all core components into a single, compact body.

-

Quick-Change UVC Lamp Modules: Facilitates easy maintenance and lamp replacement.

-

Integrated Conveyor Drive: Space-saving motorized roller or central drive system.

-

Basic Control Panel: Includes speed controller, indicator lights, and power switches.

Product Description

This Compact UV Sterilization Unit is a cost-effective, space-optimized solution that doesn't compromise on performance. Ideal for SMEs, pilot plants, or auxiliary lines in larger facilities, it employs the same proven 254nm UVC technology to deliver reliable surface decontamination inside packaging. It helps achieve significant hygiene improvement with a lower initial investment. Its flexibly customizable mounting options allow deployment at key control points like pre-fill, pre-cap, or pre-pack stages.

Technical Parameters

| Parameter Category | Specification | Notes / Customizable Options |

|---|---|---|

| Base Model | UVS-1500-ES | |

| Power Supply | Single-Phase 220VAC, 50/60Hz | |

| Total Installed Power | Approx. 0.8 - 1.2 kW | |

| UVC Light Source | 6 x Standard Quartz Germicidal Lamps, 40W each | ~8,000 hour lifespan |

| Effective Germicidal Wavelength | 254 nm | |

| Sterilization Efficacy | ≥ 99.9% | |

| Conveyor Speed | Steplessly adjustable, 0.3 - 3.0 meters/minute | |

| Machine Footprint (LxWxH) | 1500 x 600 x 900 mm | Width and Height are customizable for standard product ranges |

| Conveyor Belt Material | Food-Grade PU Belt | |

| Housing Material | 304 Stainless Steel | |

| Control System | Simple Speed & Timer Controller with digital display | Optional upgrade to basic PLC control available |

| Installation | Free-standing; leg height customizable for line integration |

Application

-

Small-batch production of food containers, jars, and cups.

-

Molded pulp sampling lines or low-to-medium speed production.

-

Supplementary sterilization point in existing lines.

-

Laboratory, R&D, or pilot-scale testing of packaging.

Customization

We provide flexible customization options to suit diverse needs:

-

Size Adaptation: Conveyor width and tunnel height can be modified for common product sizes.

-

Lamp Configuration: Number of lamps can be adjusted (e.g., 4 or 8 lamps) based on required microbial log reduction.

-

Infeed/Outfeed: Custom guide plates or connection flaps for easier line interfacing.

-

Feature Upgrade: Optional UV intensity monitor or basic data logger.

Feature

-

Space-Efficient Design: Minimal footprint allows installation in constrained spaces.

-

Plug & Play Operation: Simple setup with quick installation and commissioning.

-

Low Operational Cost: Energy-efficient lamps and minimal maintenance requirements.

-

User-Friendly: Intuitive controls require minimal training.

-

Versatile Placement: Can be used as a stand-alone unit or integrated into a line segment.

Support and Services

-

Remote installation support and detailed manual provided.

-

Email and phone technical support.

-

Access to online spare parts ordering.

Packing and Shipping

-

Standard export carton with reinforced foam cushioning.

-

Shipped via air or sea freight; lead time 15-25 working days.

FAQ

-

Q: Can this unit be connected to my existing conveyor?

A: Yes, the infeed and outfeed heights can be customized to match your current line height for smooth integration. -

Q: Is it suitable for sterilizing both plastic and molded pulp?

A: Absolutely. The 254nm UVC light is effective on most non-porous and semi-porous surfaces common in packaging.