High-Efficiency Automated Gantry Robot for Pulp Molding - Customized Handling and Stacking System for Wet and Dry Molds

Product Details:

| Place of Origin: | China |

| Brand Name: | OSMANUV |

| Certification: | ISO9001 |

| Model Number: | OSM-GT-1320 |

| Document: | CE-Single station spin caot...ne.pdf |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Wooden Box |

| Delivery Time: | 30~45 Days |

| Payment Terms: | T/T |

| Supply Ability: | Negotiation |

|

Detail Information |

|||

| Speedrange: | 1-100 M/min | Weight: | Varies, Typically 500-2000 Kg |

|---|---|---|---|

| Applicable Industries: | Manufacturing Plant | Warranty: | 1 Year |

| Electric Power: | 136.85kw | Single Class Capacity: | 13000pcs/hour |

| Color: | Customized | Feature: | Efficient |

| Feature: | Efficient | ||

| Highlight: | Automated gantry robot for pulp molding,Customized handling system for wet molds,Stacking system for dry molds |

||

Product Description

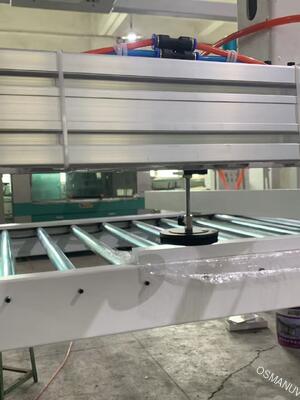

High-Efficiency Automated Gantry Robot for Pulp Molding - Customized Handling and Stacking System for Wet and Dry Molds

Production Line Composition:

This system integrates a gantry robot as the core, connecting the pulp molding forming machine, drying line, and hot pressing/sizing station. It includes a customized end-effector (e.g., multi-cavity vacuum gripper), a precision servo-driven positioning system, and a central control cabinet synchronized with the production line PLC.

Product Description:

Our automated gantry manipulator is engineered specifically for the pulp molding industry. It automates the critical process of transferring delicate, wet pulp moldings from forming dies to drying carriers or presses. The system significantly reduces labor, minimizes product damage during handling, and ensures consistent placement for uniform drying. Key components, including gripper design and motion path, are fully customizable to match your specific product geometry and production rhythm.

Technical Parameters:

| Parameter Category | Specification |

|---|---|

| Model | Gantry-PM-1500H |

| Axis (X/Y/Z) | 3 Linear Axes (4th Rotary Axis Optional) |

| Working Envelope (LxWxH) | 3000mm x 1500mm x 800mm (Customizable) |

| Maximum Load Capacity | 15 kg (includes end-effector) |

| Positioning Repeatability | ±0.1 mm |

| Maximum Speed (X/Y) | 2.0 m/s |

| Drive System | AC Servo Motors & Precision Ball Screws |

| Control System | Industrial PC + Advanced Motion Controller |

| End-Effector Interface | Pneumatic & Electrical, Customizable for vacuum or mechanical grip |

| Protection Rating | IP54 (Higher available as customization) |

| Communication Interface | Ethernet/IP, Profinet, Modbus TCP |

Application:

Fully automatic handling of pulp molded products such as egg trays, fruit trays, industrial packaging, and tableware between forming, drying, and pressing stations.

Customization:

We offer extensive customization including gripper design for complex shapes (e.g., tall coffee cup holders), adaptive vacuum systems for porous products, integration with vision systems for quality inspection during pick-up, and synchronization with various drying tunnel designs.

Feature:

-

Product-Specific Gripper: Designed to handle fragile, wet pulp molds without deformation.

-

High-Speed Cycle Time: Optimized acceleration profiles for maximum throughput.

-

Energy Efficient: Regenerative servo drives reduce overall power consumption.

-

Easy Integration: Standard communication protocols for seamless PLC integration.

Support and Services:

We provide on-site installation & commissioning, comprehensive operator & maintenance training, remote troubleshooting support, and a readily available spare parts program.

Packing and Shipping:

The gantry robot is shipped in a robust, weather-proof wooden crate. All critical components are internally secured and protected with anti-corrosion materials. Detailed installation manuals are included.

FAQ:

-

Q: Can it handle different product sizes on the same line?

-

A: Yes, with a customized quick-change gripper system or a multi-program selector, changeover can be done in minutes.

-

-

Q: How does it handle very wet and sticky products?

-

A: Our customizable vacuum system includes anti-clogging filters and moisture traps, and gripper surface materials can be specified for optimal release.

-