Customizable Two-Roll Coating Machine for Diverse Substrates - Glass, Metal, Composite Boards

Product Details:

| Place of Origin: | China |

| Brand Name: | OSMANUV |

| Certification: | ISO9001 |

| Model Number: | OSM-GT-1320 |

| Document: | Two-roller coating machine.pdf |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Wooden Box |

| Delivery Time: | 30~45 Days |

| Payment Terms: | T/T |

| Supply Ability: | Negotiation |

|

Detail Information |

|||

| Machinery Test Report: | Provided | Type: | Coating Machine |

|---|---|---|---|

| Convey Direction: | From Left To Right | Roller Speed: | 0-20m/min |

| Coating Type: | Roller Coating | Dry Way: | IR Lamp |

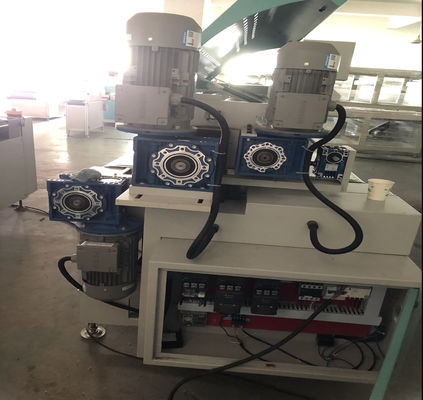

| Powersupply: | 220V/380V, 50Hz/60Hz | Production Cycle: | 45 Days |

| Condition: | New | ||

| Highlight: | customizable two-roll coating machine,roller coating equipment for glass,metal substrate coating machine |

||

Product Description

Customizable Two-Roll Coating Machine for Diverse Substrates - Glass, Metal, Composite Boards

Content:

Composition of Production Line:

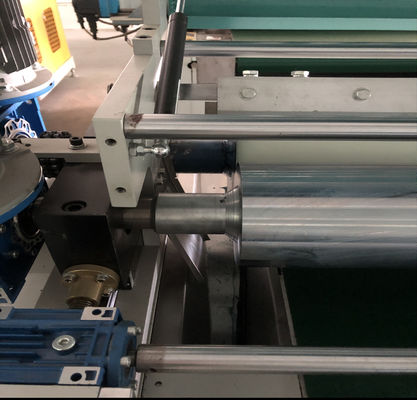

A flexible coating solution featuring a substrate cleaner, adjustable dual-roller coating head, infrared pre-dryer, and a conveyor tailored to material weight. Each section is highly customizable for diverse materials.

Product Description:

This versatile two-roll coating machine delivers precise and repeatable coating applications across a wide range of rigid sheets, from delicate glass to heavy-gauge metal, thanks to its adaptable roller pressure and gap control system.

Technical Parameters:

| Parameter | Specification | Notes |

|---|---|---|

| Suitable Materials | Glass, Metal, PVC, Composite Panels | Roller sets are customizable |

| Max. Panel Thickness | 50 mm | Adjustable guide rails |

| Coating Speed | 1 - 20 meters/min | Wide range for different coatings |

| Roller Diameter | 150 mm / 200 mm Standard | Other sizes upon request |

| Control System | PLC + Touch Screen HMI | Recipe storage for different products |

| Machine Footprint | Compact design, variable length | Customizable per layout |

Application:

Perfect for manufacturers dealing with multiple materials, such as signage makers, architectural panel producers, and industrial component suppliers requiring coatings like UV paint, ceramic ink, or adhesive.

Customization:

Core customization includes material-specific roller covers, corrosion-resistant frames for wet environments, and special feed systems for fragile glass or large panels.

Feature:

-

Rapid-change roller system for different coating materials.

-

Easy-clean design reduces downtime between batches.

-

Rugged construction for 24/7 industrial environments.

-

Precision micrometer for fine gap adjustment.

Support and Services:

Lifetime consulting support, annual maintenance contracts, and video call troubleshooting are available to ensure optimal machine performance.

Packing and Shipping:

Export-standard seaworthy packing with desiccant bags and reinforced edges. Shipment tracking provided from our factory to your site.

FAQ:

-

Q: Can I switch from water-based to solvent-based coating easily?

A: Yes, with a customized roller and wiper material set designed for chemical compatibility. -

Q: What about after-sales service?

A: We offer a 12-month warranty and have service engineers available for overseas dispatch. -

Q: Can the machine be automated?

A: Absolutely. Integration with robotic loaders/unloaders is a common customization.