High-Speed One-Pass Digital Printer for Inline High-Resolution Printing on Pulp Molded Packaging

Product Details:

| Place of Origin: | China |

| Brand Name: | OSMANUV |

| Certification: | ISO9001 |

| Model Number: | OSM-DP-600 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Wooden Box |

| Delivery Time: | 30~45 Days |

| Payment Terms: | T/T |

| Supply Ability: | Negotiation |

|

Detail Information |

|||

| Conveyor Belt: | PVC | Application: | Paper Product Printing |

|---|---|---|---|

| Power: | 3KW | Effective Width: | 600mm |

| Type: | Digital Printing Machine | Max Varnishing Size: | 720 * 1040 Mm , 1100 * 1450 Mm |

| Powersupply: | 220V/380V | Total Power: | 170kw |

| Highlight: | high-speed digital printer for pulp packaging,inline UV coating machine for printing,one-pass printer for molded packaging |

||

Product Description

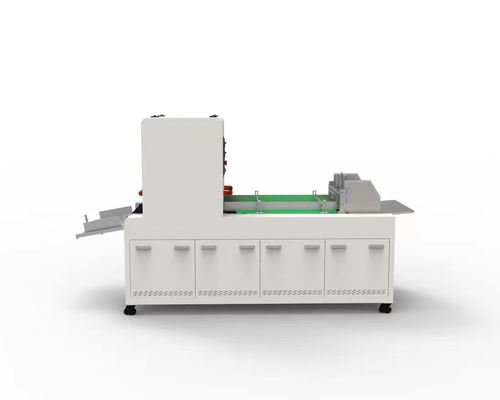

High-Speed One-Pass Digital Printer for Inline High-Resolution Printing on Pulp Molded Packaging

Product Description

This eco-friendly Single-Pass Digital Printing System is specifically engineered for high-quality, direct-to-object printing on the complex and often irregular surfaces of molded pulp products. Utilizing advanced printhead technology and a fully customizable ink delivery system, it applies vibrant, scratch-resistant graphics and text in a single pass at production line speeds. It is designed to handle the natural texture and dimensional variance of sustainable pulp packaging without the need for pre-treatment, making it an ideal solution for brands seeking to add high-value decoration to eco-friendly packaging.

Composition of Production Line

This unit is designed as a core printing module within an automated packaging line:

-

Pulp Molding & Drying Line

-

Post-Pressing & Quality Sorting Station

-

Eco-Friendly Single-Pass Digital Printer (This Unit)

-

Integrated UV/LED or Infrared Drying/Curing Unit

-

Automated Handling & Stacking Robot

-

Packaging and Palletizing System

Technical Parameters

| Parameter Category | Specification | Details / Customizable Options |

|---|---|---|

| Printing Technology | Single-Pass Piezo Inkjet | Configurable with customizable printhead arrays for resolution and speed balance. |

| Maximum Substrate Size | L 400mm x W 300mm x H 150mm (Standard) | Conveyor and gantry system are fully customizable for larger products. |

| Printing Resolution | Up to 600 x 600 DPI | Resolution and speed modes are user-selectable and customizable per job. |

| Line Speed | Up to 60 meters/minute (depending on resolution) | Speed can be customized and synchronized with your conveyor system. |

| Ink Type | UV-Curable or Water-Based Inks (Optional) | Ink system is customizable; eco-friendly, low-VOC options available. |

| Color Configuration | CMYK (Standard), + White, + Primer | Fully customizable color stations based on application needs. |

| Substrate Handling | Servo-Driven Belt Conveyor with Custom Fixtures | Tailored nest/holder design for specific product shapes to ensure stability. |

| Vision System | Integrated CCD for Automatic Print Registration | Essential for handling product variance; customizable fiducial recognition. |

| Control System | Industrial PC with RIP Software | Supports variable data printing (QR codes, serial numbers); UI can be customized. |

| Power Requirements | 220V/380V, 50/60Hz | Customizable to match regional factory power standards. |

Application

-

Direct printing of logos, graphics, and text on molded pulp food containers (clamshells, trays, bowls).

-

Printing product information and branding on egg cartons, fruit trays, and wine shippers.

-

Applying batch codes, expiry dates, and unique identifiers (QR codes) on industrial protective packaging.

-

Decoration of consumer electronics pulp packaging and gift boxes.

Feature

-

True Single-Pass Operation: Achieves high-quality printing at production line speeds.

-

Exceptional Substrate Adaptability: Specialized software and hardware compensate for surface texture and minor dimensional changes.

-

Eco-Conscious Design: Compatible with water-based and low-VOC UV inks, aligning with sustainable packaging goals.

-

High Uptime & Reliability: Designed for industrial 24/7 operation with minimal maintenance.

-

Quick Job Changeover: Digital files enable instant design changes; fixtures are easily swapped for different products.

Customization

We provide tailored solutions to match your specific production environment and products:

-

Fully Customizable print width and conveyor system to fit your product size range.

-

Tailored ink chemistry selection (food-safe, biodegradable options) and curing system.

-

Custom-engineered product holders and nesting solutions for optimal print positioning.

-

Specialized software features, such as specific barcode/QR code generation or database connectivity.

-

Brand-matching machine enclosure color and control panel layout.

Support and Services

-

Pre-Sales Application Testing with your sample products.

-

Custom Line Integration Engineering and On-Site Installation.

-

Comprehensive Operator, Maintenance, and RIP Software Training.

-

Dedicated Remote Technical Support and Preventive Maintenance Plans.

-

Guaranteed Supply of Custom Consumables (Inks, Printheads, Parts).

Packing and Shipping

-

Machine is disassembled into key modules and packed in heavy-duty, weatherproof wooden crates.

-

Sensitive components (printheads, electronics) are packed separately with anti-static and shock-absorbing materials.

-

Customized packing lists and detailed assembly drawings provided for your logistics team.

-

Shipping terms: EXW, FOB, CIF, or DAP based on customer preference. Full installation supervision available.

FAQ

Q1: Can this printer handle the uneven and porous surface of molded pulp?

A: Absolutely. This is a core strength. The system combines customizable printhead height adjustment, specialized ink formulations, and advanced software to manage surface topography and ink absorption, ensuring consistent print quality.

Q2: Are the inks used safe for food packaging applications?

A: Yes. We offer a range of customizable ink options, including food-contact compliant UV and water-based inks that meet relevant international safety standards (e.g., FDA, EuPIA). We will recommend the appropriate ink for your specific application.

Q3: How does the system handle different product shapes without slowing down?

A: The conveyor uses custom-designed fixtures or nests to securely hold each product. An integrated vision system instantly locates each item and adjusts the print coordinates on-the-fly, allowing for continuous “print-on-the-fly” operation without stopping.

Q4: What is the typical maintenance required, and what is the cost of ownership?

A: Routine maintenance includes regular printhead cleaning and occasional replacement. The modular design makes servicing straightforward. We provide customized service contracts to predict and manage operational costs, including ink consumption analysis and preventive parts replacement.