High-Efficiency UV-C Conveyor Tunnel for Continuous Food Surface Sterilization | Customizable for Packaged Goods

Product Details:

| Place of Origin: | China |

| Brand Name: | OSMANUV |

| Certification: | ISO9001 |

| Model Number: | OSM-SJ-1320 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Wooden Box |

| Delivery Time: | 30~45 Days |

| Payment Terms: | T/T |

| Supply Ability: | Negotiation |

|

Detail Information |

|||

| Weight: | 5 Kg | Safetyfeatures: | UV Protective Cover And Automatic Shutoff |

|---|---|---|---|

| Timer Control Range: | 0-99min | Irradiation Intensity: | ≥90mw/cm2 |

| Conveyor Speed: | 25~80m/min | Condition: | New |

| Temperature Control Range: | 0-99℃ | Powerconsumption: | 150W |

| Highlight: | UV-C conveyor tunnel for food sterilization,Customizable UV-C sterilization for packaged goods,High-efficiency UV irradiation machine |

||

Product Description

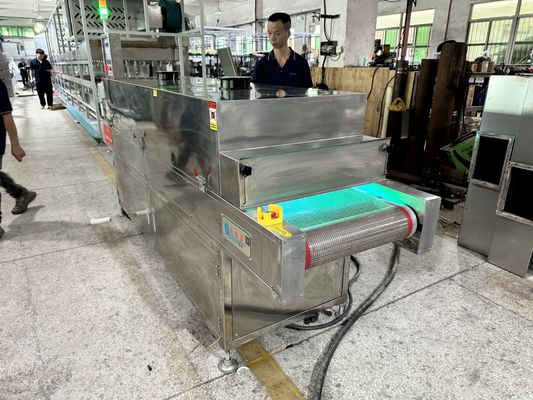

High-Efficiency UV-C Conveyor Tunnel for Continuous Food Surface Sterilization | Customizable for Packaged Goods

Product Description:

Our industrial-grade UV-C conveyor sterilization tunnel is engineered to deliver non-thermal, chemical-free disinfection for food surfaces and primary packaging. Utilizing high-output germicidal UV-C lamps, it effectively reduces pathogenic and spoilage microorganisms (such as E. coli, Salmonella, Listeria) to enhance product safety and shelf life. The system features a highly customizable stainless-steel enclosure and conveyor belt to fit seamlessly into existing production flows.

Composition of Production Line:

-

Infeed Conveyor Section (Synchronizable)

-

Stainless Steel Process Tunnel with Safety Interlocks

-

High-Output Germicidal UV-C Lamp Arrays (Top & Bottom)

-

Customizable Reflective Chamber for Maximum Intensity

-

Variable Speed Control Drive System

-

Real-time UV Intensity Monitoring Sensors

-

Exhaust Ventilation System (Optional)

-

Outfeed Conveyor Section

-

Main Control Panel with HMI Touchscreen

Technical Parameters:

| Parameter Category | Details & Specifications |

|---|---|

| Sterilization Technology | Continuous-wave Germicidal UV-C (254nm) or Pulsed Light (Customizable) |

| Effective UV Dose | Adjustable, typically 10 - 100 mJ/cm² (Customizable based on belt speed) |

| Conveyor Belt Type | FDA-approved food-grade mesh or solid belt; width customizable (e.g., 300mm, 600mm, 1000mm) |

| Conveyor Speed | Variable, 0.1 - 5 meters/minute (speed determines UV dose) |

| Lamp Configuration | Modular lamp arrays; number and power customizable |

| Power Requirements | 380V / 50Hz or customizable to regional standards (e.g., 480V / 60Hz) |

| Control System | PLC with HMI; data logging; automatic lamp life monitoring |

| Construction Material | 304 or 316 Stainless Steel (contact parts) |

| Safety Features | Safety interlocks, UV-blocking viewing windows, automatic shutdown on door opening |

Application:

Ideal for surface decontamination of baked goods, fresh produce, meats, cheeses, sushi, ready-to-eat meals, as well as for treating packaging materials like trays, clamshells, bottles, and films before filling.

Customization:

We provide extensive customization to meet specific process needs. Options include conveyor width/length, belt type, UV lamp intensity and layout, integration with upstream/downstream equipment, and material finishes (e.g., IP65 washdown rating for high-hygiene zones).

Feature:

-

Chemical-Free & Residue-Free: Safe for food contact, no chemical residues or taste alteration.

-

Low Operating Cost: Energy-efficient compared to thermal methods; minimal maintenance.

-

Instantaneous Effect: Microorganisms are inactivated instantly upon exposure at the correct dose.

-

Validatable Process: Enables critical control point (CCP) validation with dose monitoring.

-

Hygienic Design: Smooth surfaces, easy to clean and maintain.

Support and Services:

Comprehensive support package includes installation supervision, operational training, performance validation protocol assistance, spare parts supply, and preventive maintenance contracts.

Packing and Shipping:

Equipment is securely packaged in weatherproof wooden crates with internal bracing. Standard shipping terms are FOB, with CIF/DAP options available upon request.

FAQ:

-

Q: Does UV-C affect the taste, color, or nutrients of food?

-

A: When used at appropriate doses for surface treatment, UV-C has minimal to no impact on the sensory or nutritional qualities of most foods.

-

-

Q: Can this system be integrated into my existing packaging line?

-

A: Yes. The modular and customizable design allows us to adapt the inlet/outlet, conveyor height, and speed to match your line seamlessly.

-

-

Q: How is the effective UV dose controlled and monitored?

-

A: The system uses calibrated UV sensors and PLC control. The dose is controlled by adjusting conveyor speed and is logged for process validation.

-

-

Q: Are there safety concerns regarding UV radiation leakage?

-

A: No. The chamber is fully enclosed with safety interlocks that instantly cut power to UV lamps if any access panel is opened during operation.

-

-

Q: What is the lead time for a custom-configured system?

-

A: Lead time varies based on the level of customization. Standard models have shorter lead times, while fully bespoke systems require detailed engineering. We provide a project timeline after finalizing specifications.

-