24-Station High-Speed Spin Coating Line for Pulp Molded Packaging

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | OSMANUV |

| Certification: | ISO9001 |

| Model Number: | OSM-XT-1024T |

| Document: | Version 2.0 of 24-station s...on.pdf |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | Negotiation |

| Packaging Details: | WOOD PAKAGING |

| Delivery Time: | 30 |

| Payment Terms: | T/T |

| Supply Ability: | Negotiation |

|

Detail Information |

|||

| Product Name: | 24-station Spin Coating Machine | Condition: | New |

|---|---|---|---|

| Warranty: | 1 Year | Automatic Grade: | Automatic,Semi-Automatic,yes |

| Voltage: | 380V, 50Hz | Usage: | Water Based Barrier Coat, Water-proof, Oil-proof, High Temperature Proof |

| Dimension(l*w*h): | 440x345x260(mm),200*120*100mm,140mm*90mm*240mm,85x65x95,248*338*550m | Packaging Material: | Plastic,Glass,Wood,Metal,Paper Plastic Wood Glass |

| Highlight: | 24-station spin coating line,high-speed pulp molding coater,spin coating machine for packaging |

||

Product Description

24-Station High-Speed Spin Coating Line for Pulp Molded Packaging - Fully Automated Solution

Composition of Production Line:

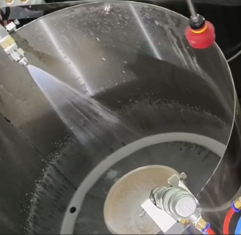

This integrated system features an automatic infeed conveyor, a 24-station rotary indexing table with precision custom fixtures, enclosed spray booths (with automatic spray guns), an integrated multi-zone IR drying tunnel, UV curing station, cooling section, automatic unloading robotic arm, and a centralized PLC control cabinet with a large HMI touchscreen.

Product Description:

Our 24-station automated rotary spray coating line is engineered for high-volume production, applying a consistent and high-quality internal barrier or decorative coating to pulp-molded products like food containers and electronic packaging. The high number of stations allows for simultaneous processing, maximizing throughput.

Technical Parameters:

| Parameter Category | Specification | Notes |

|---|---|---|

| Number of Stations | 24 Stations | Standard layout, customizable |

| Indexing Cycle Time | 15-45 seconds | Adjustable for coating and drying requirements |

| Coating Thickness | 10-50 μm | Precisely controllable |

| Power Supply | 380V / 50Hz / 3Phase | Customizable to local voltage standards |

| Total Power | ~60 kW | Depends on heating and automation configuration |

| Air Consumption | 0.7 MPa, >2.5 m³/min | Clean, dry air required |

| Control System | Siemens/Omron PLC + HMI | Recipe management and data logging |

| Estimated Output | 1500-2000 pcs/hr | Varies based on cycle time and product size |

Application:

Ideal for high-volume application of water/oil barrier coatings for food-grade pulp packaging (e.g., bowls, cups, clamshells), and flame-retardant coatings for electronic trays.

Customization:

We offer highly customizable solutions. The fixture design, spray gun number and type, drying/curing technology (IR, UV, thermal), and automation integration can be tailored to your specific product and factory layout.

Feature:

- High Throughput: 24-station design ensures maximum production capacity and efficiency.

- Precision Coating: Ensures uniform coating coverage on complex 3D shapes.

- Closed-Loop Control: Stable and consistent indexing movement for reliable operation.

- Energy Efficient: Zoned drying reduces energy consumption.

Support and Services:

We provide turnkey service including installation, commissioning, comprehensive operator training, remote troubleshooting, and a 12-month warranty on parts.

Packing and Shipping:

The line is disassembled into modular sections (table, conveyor, oven, etc.). All components are securely packed in export-worthy wooden crates with waterproof and shock-absorbent materials. Shipped via sea freight.

FAQ:

- Q: What is the main advantage of 24 stations?

- A: It allows for a longer dwell time for drying and curing within a single rotation, enabling a faster overall cycle time and higher output compared to machines with fewer stations.

- Q: Can the fixture design be changed for different products?

- A: Yes, the product-specific fixtures are customizable and can be quickly changed for production flexibility.