High-Performance Conveyor Roller Manufacturing Machine with Coating Efficiency ≥90%

Product Details:

| Place of Origin: | CHINA |

| Brand Name: | Osmanuv |

| Certification: | ISO9001 And CE |

| Model Number: | 1320 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Wooden Box |

| Delivery Time: | 35-45 Working days |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | According to customer's demand |

|

Detail Information |

|||

| Coating Uniformity: | ≤±2% | Coating Method: | Roller Coating |

|---|---|---|---|

| Coating Efficiency: | ≥90% | Power Consumption: | 2KW |

| Dimension: | 1800*1000*1200mm | Air Pressure: | 0.4-0.6Mpa |

| Roller Speed: | 0-20m/min | Noise Level: | ≤75dB |

| Highlight: | conveyor roller coating machine,high-efficiency roller manufacturing equipment,coating machine with 90% efficiency |

||

Product Description

Product Description:

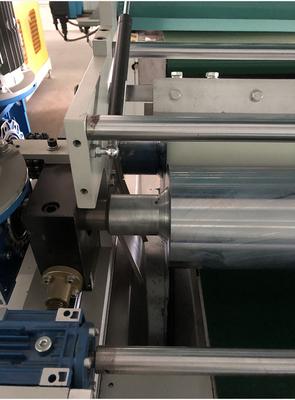

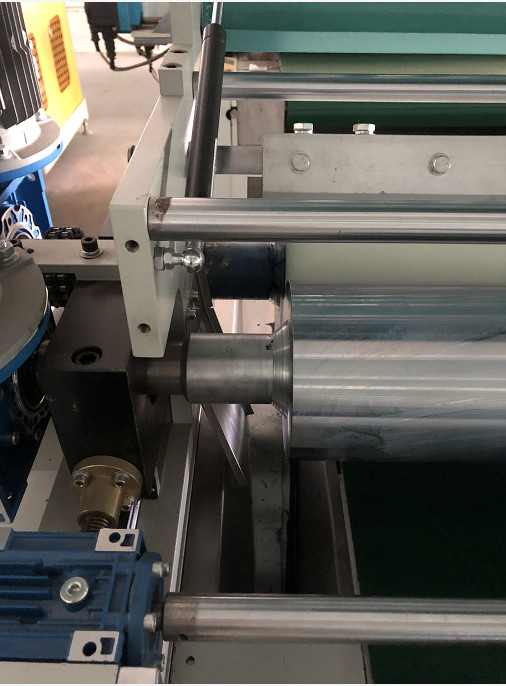

Introducing the revolutionary Roller Coating Equipment - the all-in-one solution for precision coating in industrial settings. This innovative equipment combines the functions of an Anilox Roller Cleaning Equipment and an Industrial Spray Coating Equipment, providing high efficiency, user-friendly operation, and versatile capabilities.

The Roller Coating Equipment offers a wide coating width of up to 1000mm, allowing for efficient and effective coating of large surfaces in one go. This makes it ideal for use in industrial settings where speed and productivity are crucial.

With a maximum coating thickness range of 0.2-3mm, this equipment is suitable for a variety of coating applications. Whether you need a thin, delicate coating or a thicker, more durable one, the Roller Coating Equipment can handle it all with precision and consistency.

One of the key features of the Roller Coating Equipment is its exceptional coating uniformity. With a tolerance of ≤±2%, this equipment ensures a consistent and even coating on all surfaces, eliminating the need for time-consuming touch-ups or rework.

Efficiency and cost-effectiveness go hand in hand with the Roller Coating Equipment, which consumes only 2KW of power. This not only saves energy but also reduces operating costs, making it a smart investment for any industrial facility.

The Roller Coating Equipment is designed to be compatible with the standard power supply of 220V/50Hz, making it convenient and accessible for use in various industrial settings.

The Roller Coating Equipment comes equipped with an Anilox Roller Cleaning system, which effectively and thoroughly cleans the delicate rollers without causing any damage. This ensures the longevity of the equipment and maintains its efficiency and precision over time.

The Roller Coating Equipment also functions as an Industrial Spray Coating Equipment, providing a versatile and efficient solution for various coating applications. Its spray coating technology ensures an even and precise application of coatings, making it ideal for use in industries such as automotive, furniture, and packaging.

With its advanced technology and precision engineering, the Roller Coating Equipment delivers precise and accurate coating results every time. This makes it an ideal choice for industries that require high-quality finishes and consistent coating results.

The Roller Coating Equipment is designed for high efficiency, with its wide coating width, uniform coating, and user-friendly operation. This allows for faster and more productive coating processes, reducing downtime and increasing output for industrial facilities.

The Roller Coating Equipment is designed with the user in mind, featuring a user-friendly interface and easy-to-use controls. This ensures that operators of all skill levels can use the equipment with minimal training, increasing efficiency and reducing the risk of errors.

The Roller Coating Equipment is a versatile machine that can handle a wide range of coating applications. From thin, delicate coatings to thicker, more durable ones, this equipment can do it all, making it a valuable asset for any industrial facility.

The Roller Coating Equipment is an innovative solution that combines the functions of two machines in one, providing a cost-effective and efficient solution for precision coating in industrial settings. With its advanced technology and design, this equipment is at the forefront of the coating industry.

Features:

- Product Name: Roller Coating Equipment

- Power Consumption: 2KW

- Coating Efficiency: ≥90%

- Coating Uniformity: ≤±2%

- Max Coating Width: 1000mm

- Power Supply: 220V/50Hz

- High Speed Coating Machine

- Heavy Duty Conveyor Rollers

- Conveyor Roller Manufacturing Machine

Technical Parameters:

| Technical Parameters | Value |

|---|---|

| Product Name | Conveyor Roller Manufacturing Machine |

| Coating Method | Roller Coating |

| Coating Efficiency | ≥90% |

| Roller Speed | 0-20m/min |

| Max Coating Width | 1000mm |

| Coating Material | Paint, Resin, Etc. |

| Roller Diameter | 200-400mm |

| Coating Uniformity | ≤±2% |

| Air Pressure | 0.4-0.6Mpa |

| Dimension | 1800*1000*1200mm |

| Additional Features | Anilox Roller Cleaning Equipment |

Applications:

The Roller Coating Equipment, also known as the Automatic Spray Paint Production Line, is a versatile and customizable machine designed for high efficiency and precision in coating various objects. With its heavy duty conveyor rollers and advanced technology, it is the perfect solution for all your coating needs.

The Roller Coating Equipment is widely used in various industries, such as automotive, electronics, furniture, and more. It is ideal for coating different materials such as metal, plastic, wood, and glass, making it a versatile machine for a wide range of applications.

Imagine a large manufacturing plant where different products are being coated with precision and efficiency. The Roller Coating Equipment is at the center of the production line, with its heavy duty conveyor rollers carrying the products through the various stages of coating. The fully automated process ensures consistent and uniform coating on every product, while the customizable settings allow for different coating thicknesses and types.

- Brand Name: Automatic Spray Paint Production Line

- Model Number: 1320

- Place of Origin: China

- Certification: ISO9001

- Minimum Order Quantity: 1 Set

- Price: Negotiable

- Packaging Details: Wooden box

- Delivery Time: 40 work days

- Payment Terms: T/T, Western Union

- Supply Ability: According to customer's demand

- Coating Uniformity: ≤±2%

- Power Consumption: 2KW

- Max Coating Thickness: 0.2-3mm

- Dimension: 1800*1000*1200mm

The Roller Coating Equipment is designed to provide high efficiency and precision in coating, while also being durable and customizable to meet your specific needs. Some of its key features and benefits include:

- Heavy Duty Conveyor Rollers: With its heavy duty rollers, the machine can handle heavy objects and ensure smooth movement throughout the coating process.

- High Efficiency: The fully automated process and customizable settings allow for high efficiency in coating, saving time and labor costs.

- High Precision: The machine is equipped with advanced technology, ensuring precise and uniform coating on every product.

- Fully Automated: The machine is designed for a fully automated process, reducing the need for manual labor and ensuring consistent results.

- Versatile: The machine can coat a wide range of materials and products, making it suitable for various industries and applications.

- Customizable: The machine can be customized to meet your specific coating requirements, such as thickness and type of coating.

- Durable: Made with high-quality materials, the Roller Coating Equipment is built to last and withstand heavy use.

Choose the Roller Coating Equipment for efficient and precise coating of your products. Contact us now to discuss your specific needs and get a quote.

Customization:

Brand Name: Automatic Spray Paint Production Line

Model Number: 1320

Place of Origin: China

Certification: ISO9001

Minimum Order Quantity: 1 Set

Price: Negotiable

Packaging Details: Wooden box

Delivery Time: 40 work days

Payment Terms: T/T, Western Union

Supply Ability: According to customer's demand

Coating Method: Roller Coating

Power Consumption: 2KW

Coating Efficiency: ≥90%

Roller Diameter: 200-400mm

Noise Level: ≤75dB

Our Roller Coating Equipment, the Automatic Spray Paint Production Line, is a top-of-the-line product designed and manufactured in China. With ISO9001 certification, our equipment guarantees quality and reliability.

We offer customized services to meet the specific needs of our customers. Our minimum order quantity is 1 set, and the price is negotiable based on the customer's requirements. The packaging is done in a sturdy wooden box to ensure safe delivery.

The delivery time for our Roller Coating Equipment is 40 work days. We accept payments through T/T and Western Union, making it convenient for our customers to make transactions.

Our equipment uses the highly efficient Roller Coating method, consuming only 2KW of power. With a coating efficiency of ≥90%, our equipment ensures a smooth and even coating on your products. The roller diameter can be adjusted between 200-400mm to suit your coating needs.

Our Heavy Duty Conveyor Rollers are designed to handle heavy loads, making it perfect for industrial use. We also offer a Conveyor Roller Manufacturing Machine for those who want to produce their own rollers.

With a noise level of ≤75dB, our equipment operates smoothly and quietly, creating a conducive working environment. We can supply according to the customer's demand, ensuring that you have the right equipment for your specific needs.

Choose our Roller Coating Equipment for a high-quality, efficient and customizable solution to your coating needs. Contact us now for more information and to place your order.

Packing and Shipping:

Our Roller Coating Equipment is carefully packaged to ensure safe delivery to our customers. The equipment is first wrapped in protective materials to prevent any damage during transit. It is then placed in a sturdy wooden crate or box for added protection.

For international shipments, the equipment is securely packed in a wooden crate and placed on a pallet for easy handling. The crate is then sealed and labeled with all necessary shipping information.

For domestic shipments, the equipment is packed in a heavy-duty cardboard box with foam padding and labeled with all necessary shipping information.

We work with trusted and reliable shipping companies to ensure timely and efficient delivery of our Roller Coating Equipment to our customers worldwide. Customers can also arrange for their own shipping if desired.

Upon delivery, customers are responsible for inspecting the equipment for any damage during transit. Any issues should be reported to us immediately for resolution.

FAQ:

- Q: What is the brand name of this product? A: The brand name of this product is Automatic Spray Paint Production Line.

- Q: What is the model number of this product? A: The model number of this product is 1320.

- Q: Where is this product manufactured? A: This product is manufactured in China.

- Q: Is this product certified? A: Yes, this product is certified with ISO9001.

- Q: What is the minimum order quantity for this product? A: The minimum order quantity for this product is 1 set.

- Q: Can the price of this product be negotiated? A: Yes, the price of this product is negotiable.

- Q: How is this product packaged? A: This product is packaged in wooden boxes.

- Q: How long is the delivery time for this product? A: The delivery time for this product is 40 work days.

- Q: What are the accepted payment terms for this product? A: The accepted payment terms for this product are T/T and Western Union.

- Q: Is this product customizable according to customer's demand? A: Yes, this product is customizable according to customer's demand.