Universal Panel Laminating Machine for Metal, Glass & Furniture Boards - High-Efficiency Production Line

Product Details:

| Place of Origin: | China |

| Brand Name: | OSMANUV |

| Certification: | ISO9001 |

| Model Number: | OSM-FM-1320 |

| Document: | film Lamintaing.pdf |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Wooden Box |

| Delivery Time: | 30~45 Days |

| Payment Terms: | T/T |

| Supply Ability: | Negotiation |

|

Detail Information |

|||

| Laminating Width: | 1600mm | Machine Model: | OSM-FM-1320 |

|---|---|---|---|

| Operating Speed: | 0-13m/min | Automatic Grade: | Automatic |

| Weight Of Paper: | 125~500g/m2 | Type: | Laminating Machine |

| Machinedimensions: | 1500mm X 700mm X 1200mm | Usage: | Laminating Paper, Photos, Documents, Cards |

| Highlight: | universal panel laminating machine for metal,high-efficiency glass laminating machine,furniture board laminating production line |

||

Product Description

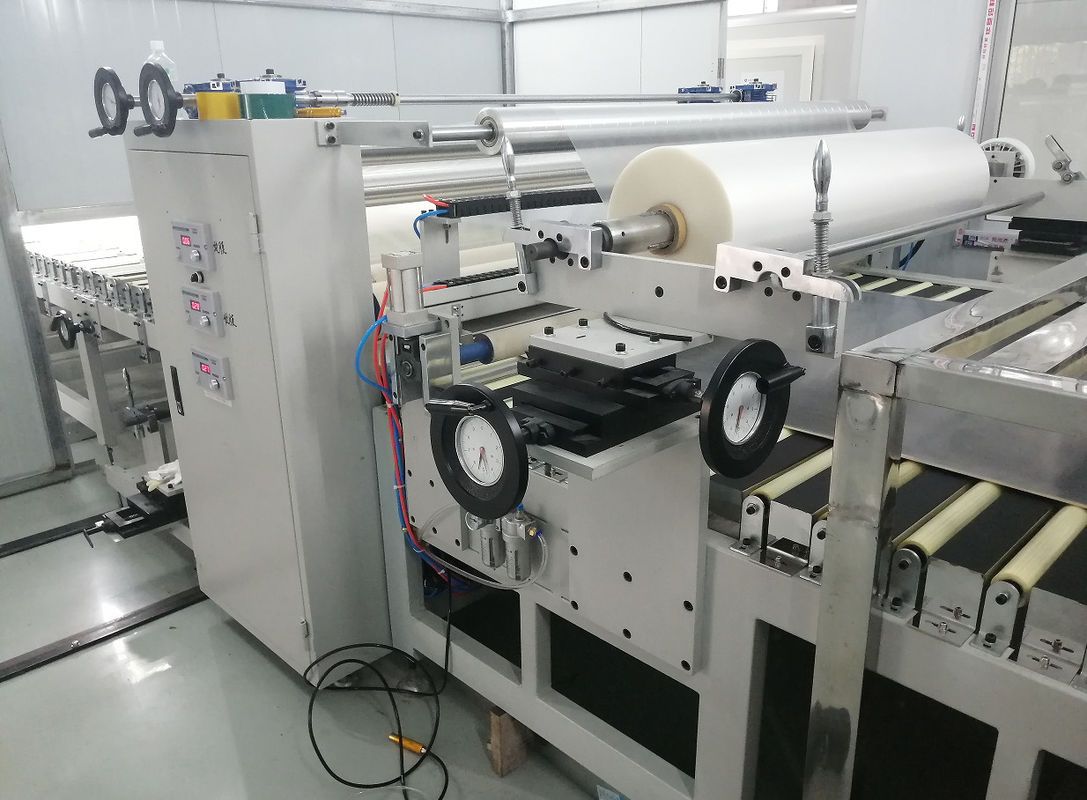

Universal Panel Laminating Machine for Metal, Glass & Furniture Boards - High-Efficiency Production Line

1. Product Description

Our advanced panel laminating machine is engineered for applying protective, decorative, or functional films onto a diverse range of rigid substrates. Utilizing precise temperature, pressure, and speed control, it ensures bubble-free, permanent adhesion on metal sheets, glass panels, and furniture boards (MDF, particle board, plywood). The fully customizable modular design allows seamless integration into both new and existing production lines for high-quality, consistent surface finishing.

2. Technical Parameters

| Parameter | Specification | Details / Customizable Options |

|---|---|---|

| Max. Panel Width | 1300mm, 1600mm, 2100mm, 2500mm | Standard sizes; width is fully customizable. |

| Panel Thickness Range | 1mm ~ 60mm | Adjustable guiding system for varied thicknesses. |

| Laminating Speed | 0-25 meters/min | Variable speed drive for optimal output. |

| Heating System | Ceramic IR Heaters / Hot Air | Selectable for different films (PVC, PET, PP, etc.). |

| Pressure System | Pneumatic / Silicone Roller | Adjustable pressure (0-10 bar) for perfect bonding. |

| Power Supply | 3-Phase, 380V / 50Hz (or as per local standard) | Customizable voltage and frequency. |

| Control System | PLC with Touchscreen HMI | Preset recipes for different materials, user-friendly. |

| Machine Frame | Heavy-duty welded steel | Robust construction for stable operation. |

3. Composition of Production Line

A customizable turnkey laminating line may include:

-

Panel Loading & Feeding Unit (Manual/Automatic)

-

Pre-Cleaning Station (Dust removal with brush/ionized air, optional for glass/metal)

-

Adhesive Application Unit (Roller coater or spray for glue-type films, optional)

-

Film Unwinding & Tension Control (Precision dancer or servo system)

-

Pre-Heating Zone (Activates adhesive for better bonding)

-

Main Laminating Nip (Heated pressure roller assembly)

-

Post-Heating/Pressing Zone (Ensures complete curing and adhesion)

-

Protective Film Application Unit (For surface protection, optional)

-

Trimming & Edge Cutting Unit (For precise edge finishing, optional)

-

Output Stacker or Conveyor (Automatic stacking or transfer)

4. Key Features & Benefits

-

Multi-Substrate Compatibility: One machine handles metal, glass, and furniture boards with quick changeover.

-

Bubble-Free Bonding: Precision roller alignment and tension control eliminate air entrapment.

-

Energy Efficient: IR heating targets the film layer directly, reducing energy waste.

-

User-Friendly Operation: PLC stores parameters for different materials; minimal training required.

-

High Durability: Critical components like rollers and bearings are industrial-grade for long life.

-

Highly Customizable: From feeding to stacking, each module can be tailored to your specific output, panel size, and film type.

5. Application Industries

-

Architectural & Interior Decoration: Laminating decorative films on metal/aluminum composite panels for ceilings, walls, and glass for privacy/decoration.

-

Furniture Manufacturing: Applying wear-resistant laminates (Melamine, PVC, acrylic) onto MDF, particle boards, and plywood for cabinets, desks, and doors.

-

Appliance & Electronics: Applying protective or functional films on metal housings and control panel glass.

-

Signage & Display: Laminating graphic films onto rigid boards for point-of-sale displays and signs.

6. Customization & Support Services

-

Process Consultation: We analyze your specific materials (substrate + film) to recommend the optimal customized machine configuration.

-

Tailored Design: Customizable in width, heating method, automation level (from semi to fully automatic), and optional add-ons.

-

Installation & Training: On-site commissioning by our engineers and comprehensive operator training.

-

After-Sales Support: Reliable spare parts supply, online/onsite technical support, and preventive maintenance plans.

7. Packing and Shipping

-

Main machine is disassembled into modular frames and functional units for safe transport.

-

All parts are securely packed in wooden crates with waterproof and shock-absorbing materials.

-

Electronic components are stored in sealed, moisture-proof boxes.

-

Detailed installation manuals, electrical drawings, and packing lists are included.

-

We handle global shipping (FOB, CIF, etc.) with standard lead times of 6-10 weeks, depending on the level of customization.

8. FAQ

-

Q: Can one machine reliably laminate such different materials (glass, metal, wood)?

-

A: Yes. The key is a highly customizable design with adjustable pressure, temperature profiles, and optional pre-treatment stations (e.g., dust removal for glass, surface treaters for metal) to ensure perfect adhesion for each material.

-

-

Q: What types of films can be applied?

-

A: The machine handles a wide range, including PVC, PET, PP, decorative veneers, and pressure-sensitive adhesive (PSA) films. The heating and pressure system can be customized for your specific film.

-

-

Q: How is alignment and avoiding wrinkles ensured for large panels?

-

A: Our system features a precision edge-guiding system (EPC) and servo-controlled film tension to maintain perfect alignment and prevent wrinkles, even at high speeds.

-

-

Q: Do you provide samples or tests?

-

A: Yes. We strongly recommend sending your actual substrate and film samples for a customized feasibility test in our demo center to verify results before order.

-