Modular AR Film Coating System for PV R&D & Pilot Production - Customizable Coating Process Platform

Product Details:

| Place of Origin: | China |

| Brand Name: | OSMANUV |

| Certification: | ISO9001 |

| Model Number: | OSM-AR-1320 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiation |

| Packaging Details: | Wooden Box |

| Delivery Time: | 30~45 Days |

| Payment Terms: | T/T |

| Supply Ability: | Negotiation |

|

Detail Information |

|||

| Power: | Electricity | Application: | Surface Coating Of Materials Such As Paper, Film, Fabric, And Metal |

|---|---|---|---|

| Automatic Grade: | Semi-automatic | Machinery Test Report: | Provided |

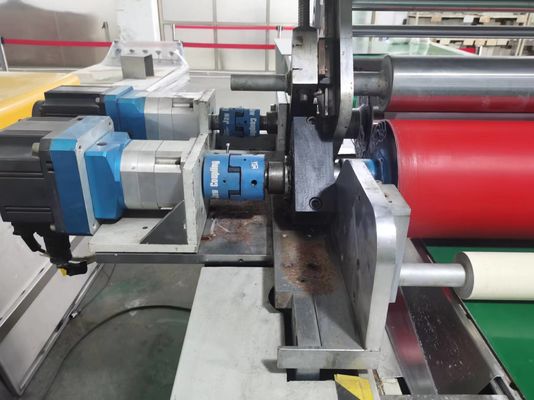

| Type: | Coating Machine | Controlsystem: | PLC Control With Touch Screen Interface |

| Coating Material: | Paint, Resin, Etc. | Material: | Natural Rubber,PVC |

| Highlight: | modular AR film coating system,customizable PV coating platform,roller coating equipment for R&D |

||

Product Description

Modular AR Film Coating System for PV R&D & Pilot Production - Customizable Coating Process Platform

Want to Know more details about this product